Product Center

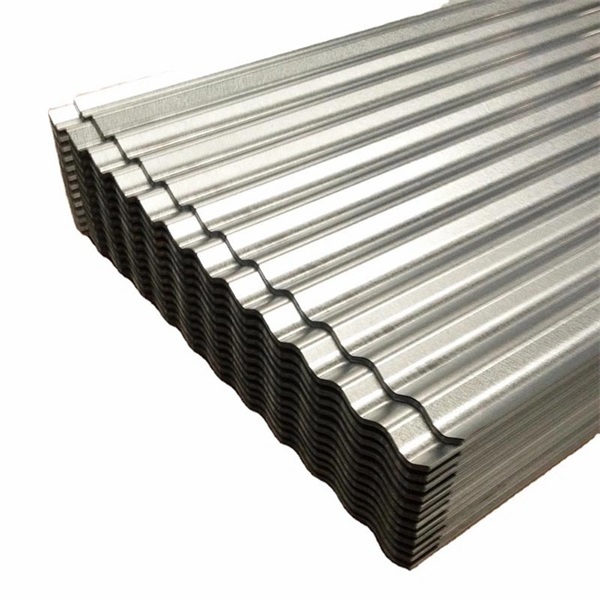

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.

Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.

Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.

Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.

Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

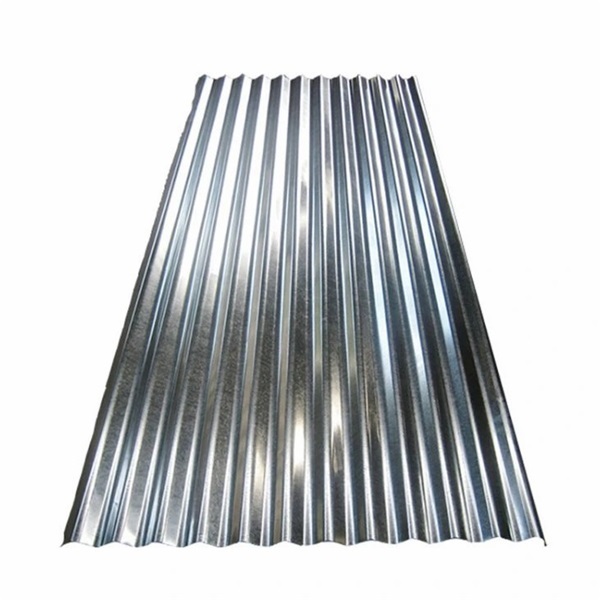

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Galvalumed sheet, with 55% aluminum zinc alloy coating on the surface. The surface of the Galvalumed sheet presents a unique smooth, flat and gorgeous star, and the basic color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the Galvalumed sheet can reach 25a, and the heat resistance is very good, which can be used in the high temperature environment of 315 ℃; The coating has good adhesion with the paint film, has good processing performance, and can be punched, sheared, welded, etc; The surface conductivity is very good.

Galvalumed sheet, with 55% aluminum zinc alloy coating on the surface. The surface of the Galvalumed sheet presents a unique smooth, flat and gorgeous star, and the basic color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the Galvalumed sheet can reach 25a, and the heat resistance is very good, which can be used in the high temperature environment of 315 ℃; The coating has good adhesion with the paint film, has good processing performance, and can be punched, sheared, welded, etc; The surface conductivity is very good.